As we are slowly transitioning into electric vehicles, the pickup world is having some issues. You see, most pickups on the current market use platforms that are similar to those normal electric sedans use. This is a problem as pickup trucks are designed to pull and haul weights and, in many cases, do it on rough terrain. This requires a very specific type of suspension and frame design, otherwise, the vehicle won’t have the durability to deal with such use. At the end of the day, pickups are designed for work. They need to be vehicles people can depend on and if that means sacrificing some comfort and handling manners then so be it. Thankfully, Ford has recently patented a design that will solve many EV pickup problems. Let’s have a look.

Why Should Pickups Have Different Suspensions

Before we get into the patent Ford has come up with, it is important to understand the reason why such a patent is important. Now, normal EVs use a unibody design with independent front and rear suspension. What does this mean? Well, a unibody design simply means that the whole vehicle is one single structure. There is no frame supporting the body, the frame is part of the body. This provides benefits when it comes to packaging, weight, and safety. Now, the independent suspension means that each wheel works independently from each other. For example, if the left wheel falls into a pothole, the right wheel won’t have to move with it. This improves handling and ride quality.

While the above designs work great on normal vehicles, they cannot cope with the use of a pickup. Such vehicles need a body on frame design (where the frame and body are separate) instead of a unibody. This makes them more durable and serviceable. From there on, we have the need of a solid axle. A solid axle is basically a solid beam that connects both wheels together; therefore, when one moves, the other moves with it. On road, this leads to poorer driving manners. However, it is more durable and can take heavy loads without sagging which makes it great for hauling and towing. The solid axle also have benefits off-road. Its design enables the vehicle to have much more wheel articulation than a vehicle with independent suspension. This means that the truck can keep its wheels in contact with the ground for longer; thus, improving stability and grip. Finally, servicing a solid axle is easier as ball joints and bushings are generally easier to change.

Ford’s Electric Solid Axle Patent

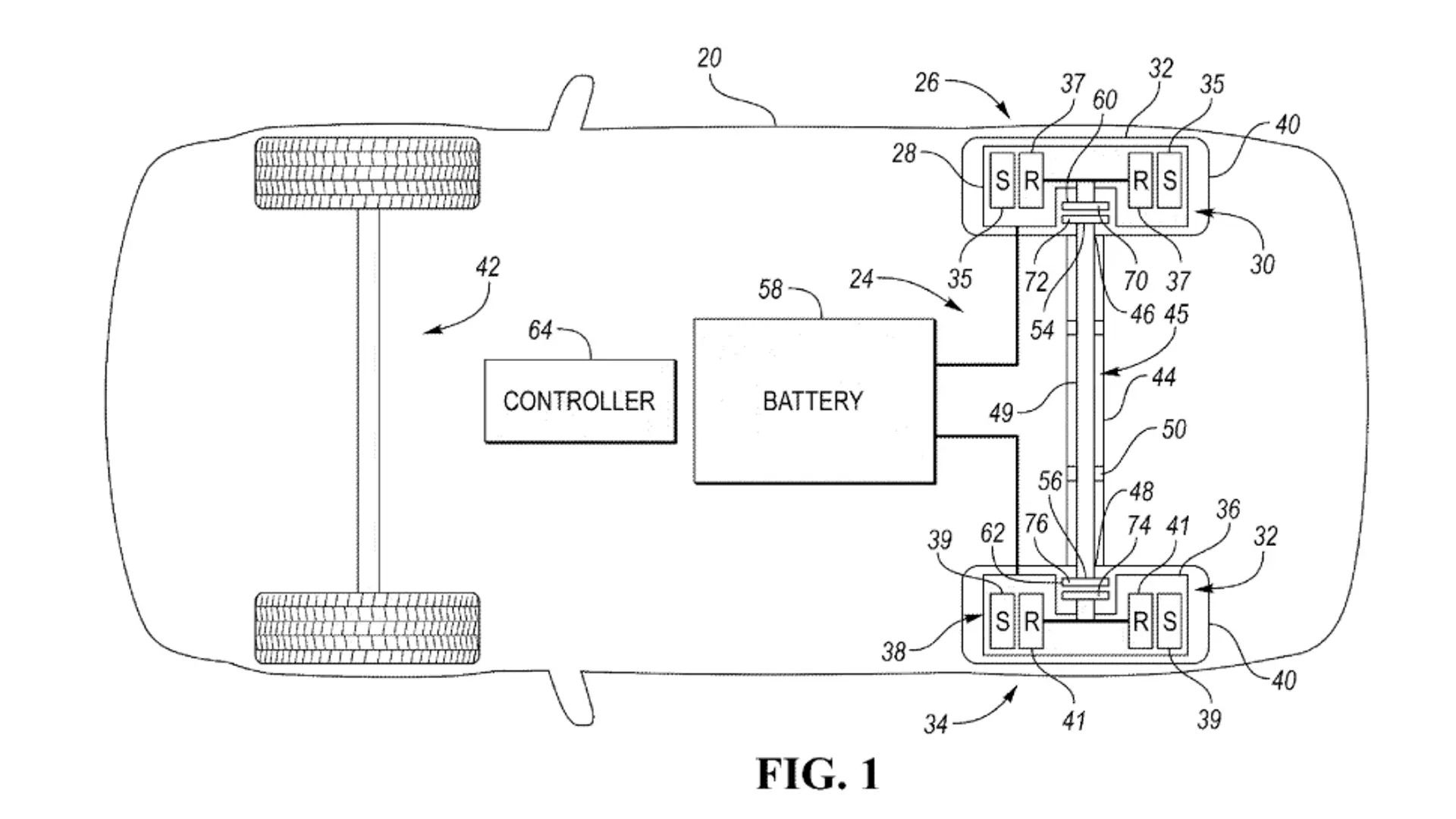

The good news is that Ford engineers are aware of the benefits a solid axle can have for trucks and have patented an electric solid axle design. The way this will work is interesting. The solid axle will work with in-hub motors that will provide drive to each specific wheel. So, four motors and four-wheel drive. Inside these hub motors, there will be clutches that can engage or disengage depending on whether that specific wheel needs power or not. For example, in an off-road situation, the vehicle can disengage a wheel that is in the air and send the power to the three wheels that are on the ground. Since all this will be controlled electronically, it will be insanely quick to function. A further positive about this design is the fact that it eliminates the need for a diff in the middle. This means that there won’t be any low spots to get hung up on when off-roading.

There Are Some Potential Drawbacks With This Design

It is worth mentioning that Ford was planning on using this design on the F-150 Lightning, but didn’t end up doing so due to durability concerns due regarding the exposed location of the motors. We believe this can be easily overcome by using protection around the motors. However, an even bigger problem here might be the heat. You see, this design means that both power and braking will be done in the same location. So, the area will get warm by the motors working and then even warmer when braking. However, this can also be overcome by utilizing a clever cooling system for the motors.

Another Clever Solid Axle Design Is In The Making

The design Ford has patented isn’t the only solution to the electric solid axle problem. ZF which is famous for its transmissions, has also come up with an electric solid axle, but this one follows a more conventional design. Here, instead of power coming from hub motors, it comes from a single motor located in the middle of the solid axle – where the gears on an ICE vehicle would normally be. This eliminates the concerns around durability and heat management as the power and brake are in separate locations and the whole assembly can be protected with something like a diff cover for normal diffs. The downside here is that the trucks will have two motors instead of four and the low-hanging point in the middle of the axle remains. Plus, it may be argued that there are more power losses since power from the motor will need to be transferred to the wheels through some type of inboard axle. In any case, we believe that it is just a matter of time before we get the chance to see both these EV axles in action. As they get used and abused, their strengths and weaknesses will be revealed for a fairer comparison.